Surface Inspection, Precise Defect Classification

Web Ranger - Surface Inspection System

Easy to use tools and simple system setup

Higher product quality, better yields and lower costs of production

The Web Ranger is an optical surface inspection and defect classification system that provides a total quality solution for products produced in continuous webs.

The highly modular design allows the system to be tailored to any application based on web width, web speed and defect size (resolution) requirements. The incorporation of smart cameras with embedded processing resources enables the system to provide real time, 100% inspection of the material and rapid, accurate detection of defects.

Precise Defect Classification

The Web Ranger’s advanced surface inspection classification engine can perform precise defect classification based on extremely subtle differences between defect categories. Using over one hundred extracted features and multiple techniques, the classification engine can be easily trained to reliably recognize distinct defect categories present in the material being inspected. Web Ranger’s superior classification performance greatly enhances product grading, process control and overall quality control.

Defects Gallery

Click any of the material category links to the right to view examples of defects that Web Ranger can detect.

Please Note: All defect sample images are visually enchanced to allow the defects to be easily visible to the human eye.

Features

Advanced Classification

precise classification of defects into user-defined categories using advanced statistical (KNN) and non-linear heuristic methods (neural networks)

SQL Database

comprehensive database of defects with images, positions and all defect features

Automatic Archiving

automatic transfer of defect data to an external device or system based on user-defined criteria

Flexible Reporting

standard and custom reports of inspection results and statistics in tabular and graphical format

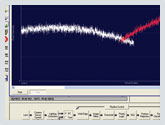

Trend Analysis

automatic detection and reporting of repeating defects

Formation Analysis

Graphical display of product quality based on calculation of a Non Uniformity Index

Defect Density

automatic defect monitoring based on user-specified criteria that assign points to defect class occurrences

Roll Grading

automatic grading of rolls based on user-specified grading criteria that assign points to defect class occurrences

Custom Digital I/O

to generate alarms, trigger marking and tagging systems, automatically start/stop jobs, etc.

Multi-Language GUI

English, German, Chinese, etc.

Factory Interfaces

Windows-based open architecture allows easy connections to other systems and devices via OPC, SQL Query, Ethernet, or custom digital interface

Access

Remote access via Internet for system maintenance and software upgrades

Support

24/7 Technical Support via Internet and Telephone Hotline

Cameras

The incorporation of smart cameras with embedded processing resources enables the system to provide 100% inspection of the material and rapid, accurate detection of defects. This allows the system to be easily optimized to inspect metallized plastic film, synthetic paper, fiberglass, woven textiles, coated nonwovens, glass and many more.

Web Ranger inspection solutions and classification libraries have been successfully proven for many industries.

Lighting

for Surface Inspection Applications

High-Intensity Illumination

Wintriss linear light sources are optimized for web inspection and the challenge of operating in a 24/7 production environment:

- High intensity to 100,000 lux

- Superior reliability up to 100,000 hours

- Modular for any width web

- Outstanding uniformity for consistent detection

- Wintriss patented lighting products are the most advanced in the industry. Our Sodium Vapor and LED linear lights are specifically designed for web inspection applications:

- HP Sodium Vapor – high intensity front light

- LED Ranger (LED) – high intensity front or back light available in multiple wave lengths and intensities, diffused or focused

- Refraction Ranger (LED) – collimated light for translucent materials

Whatever your surface inspection application, Web Ranger is a cost-effective solution that provides a rapid return on investment.

Compact, Energy-Efficient Lightsource

Proper illumination is critical to effective flaw detection performance. Lighting design must consider material texture, web speed, defect size and type, color and ambient lighting.

Wintriss lighting experts have developed and patented a series of sophisticated techniques and specialized lights that are optimized for surface inspection. We are the best in the industry at determining the most effective lighting solution for the inspection application. Wintriss has patented several innovative lighting techniques that expose extremely small defects that can't be detected by other systems. The clarity of the images produced using these techniques results in reliable detection and accurate classification.

- Modified Schlieren for plastic film and glass

- Bi-Level Lighting for 3D defects in metal, film and glass

Software

A powerful classification engine quickly and accurately sorts the defects into user-defined categories to aid in production quality control and process improvement. All defect data can be viewed in real time and is also stored in a comprehensive database for subsequent review, analysis, reporting and archiving.

Labelers

Tagger

Specification

Size 270 x 270 x 260mm( HxWxD )

Line Speed Maximum - 300 M / min

Working Speed Maximum - 10 Piece / sec Maxs

Standard Tag 20 x 30mm( LxW ) customization

Power 220V AC

Installation Install by Tracked (Can push away if unused)

- Positioner by optical fiber, and compensate inaccuracy automatically.

- Stick on products by pushing roll.

- Provide no-paper-alarm dry connect (DC 24V, 1A max).

- Stick on product by friction, it can make the working speed stablely

Marker

Specification

Function

- Real-time mark

Make sure of capillarity by woolen blanket, action by air pressure, mark near defect immediately (Automatic edge tracking) - Maximum mark speed

1600 M/min -

Maximum mark width

25mm -

Standard travel

800 mm (9 meters max) -

Reaction time

100 ms

Printing Head

- Hard woollen blanket

75 X 25 X 130 mm (Consumables) -

Ink pot

Acrylic bottle 200 C.C. -

Air pressure cylinder

Travel for 15 mm (Need air pressure 5 Kg/mm2) -

Optical fiber sensor

Omron E3X-NAII

Part of Transmission

- Motor

Smart motor (With PLC inside) -

Gear organize

High rigidity gears -

Trajectory

Low weight aluminum products -

Orientation

Orientation by OMRON EE-SX672

Electric Control

- System voltage

220V, 1Φ, 3A max -

Maximum power

250W -

Interface

RS-232 -

I/O box

350 X 450 X 200 mm

Software

- Software Update

SMI (Smart Motor Interface) -

Overseeing

HMI (Human Machine Interface)

Support & Installations

Available Worldwide

Our Web Ranger system has been installed at over 250 locations in 16 countries worldwide. With local support available across the world there is no better choice for your surface inspection needs than Wintriss.

Contact a Representative

Learn more about our products, get your questions answered or schedule consultations and installation.

Wintriss Inspection Solutions

Visit our International Distributors page or

visit the Wintriss Inspection Solutions site.

Wintriss Engineering

Visit our Contact page or

USA Toll Free: (800) 550-7300

Phone: (858) 550-7300

English

English 简体中文

简体中文 繁體中文

繁體中文